Advancing With Peptide Synthesis

A Comprehensive Overview of Growing Demand and Manufacturing Solutions

Introduction:

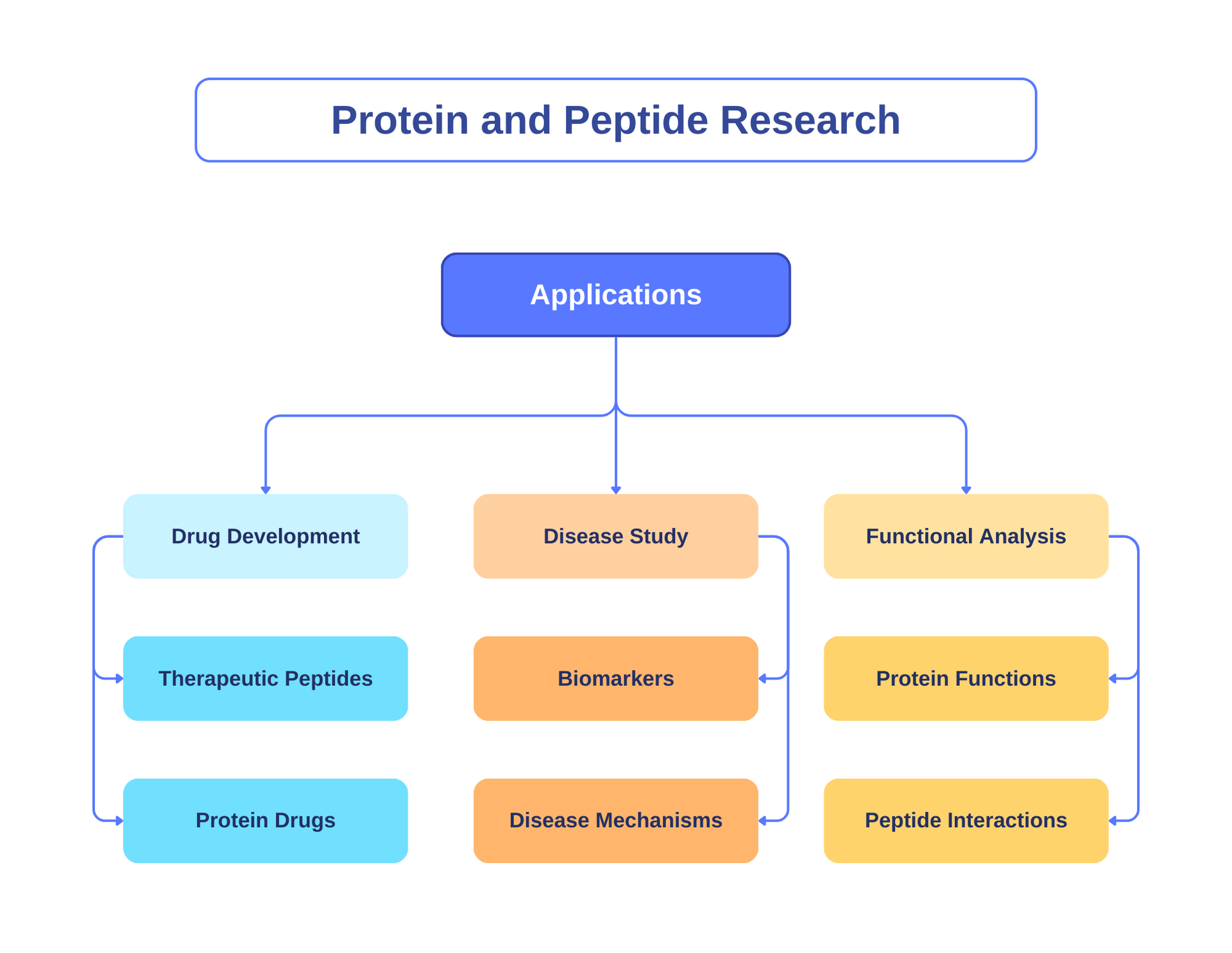

In the ever-evolving landscape of life sciences and biotechnology, the synthesis of peptides and proteins has emerged as a cornerstone for advancements in medicine, research, and therapeutic development. Peptides, short chains of amino acids, serve as essential tools in probing protein functions, designing novel drugs, and developing vaccines. With the increasing complexity of biological research and the rising need for precision in therapeutic interventions, the demand for peptide synthesis services has witnessed exponential growth. This white paper delves into the current trends, challenges, and future directions of peptide synthesis, emphasizing the critical importance of developing novel hybrid manufacturing solutions to meet these demands.

Peptide and Protein Production:

Peptide and protein production refers to the methods and processes used to synthesize these biomolecules, which are vital for various applications ranging from pharmaceuticals to nutritional supplements. Understanding the intricacies of peptide synthesis, including both chemical and biological methods, is crucial for advancing our capabilities in biotechnology.

Explore how our Peptide Synthesis solutions can enhance your research and streamline discovery.

Solid-Phase Peptide Synthesis (SPPS):

Solid-phase peptide synthesis (SPPS) is a dominant method in peptide manufacturing, wherein the peptide chain is anchored to a solid support, facilitating easier purification and assembly. This method allows for the creation of complex peptide sequences with high precision, akin to building a Lego set where each block is an amino acid. SPPS typically employs Fmoc (9-fluorenylmethyloxycarbonyl) or Boc (tert-butyloxycarbonyl) chemistry to protect amino acid residues during synthesis, ensuring accurate sequence assembly.

Advantages and Challenges of Chemical Synthesis

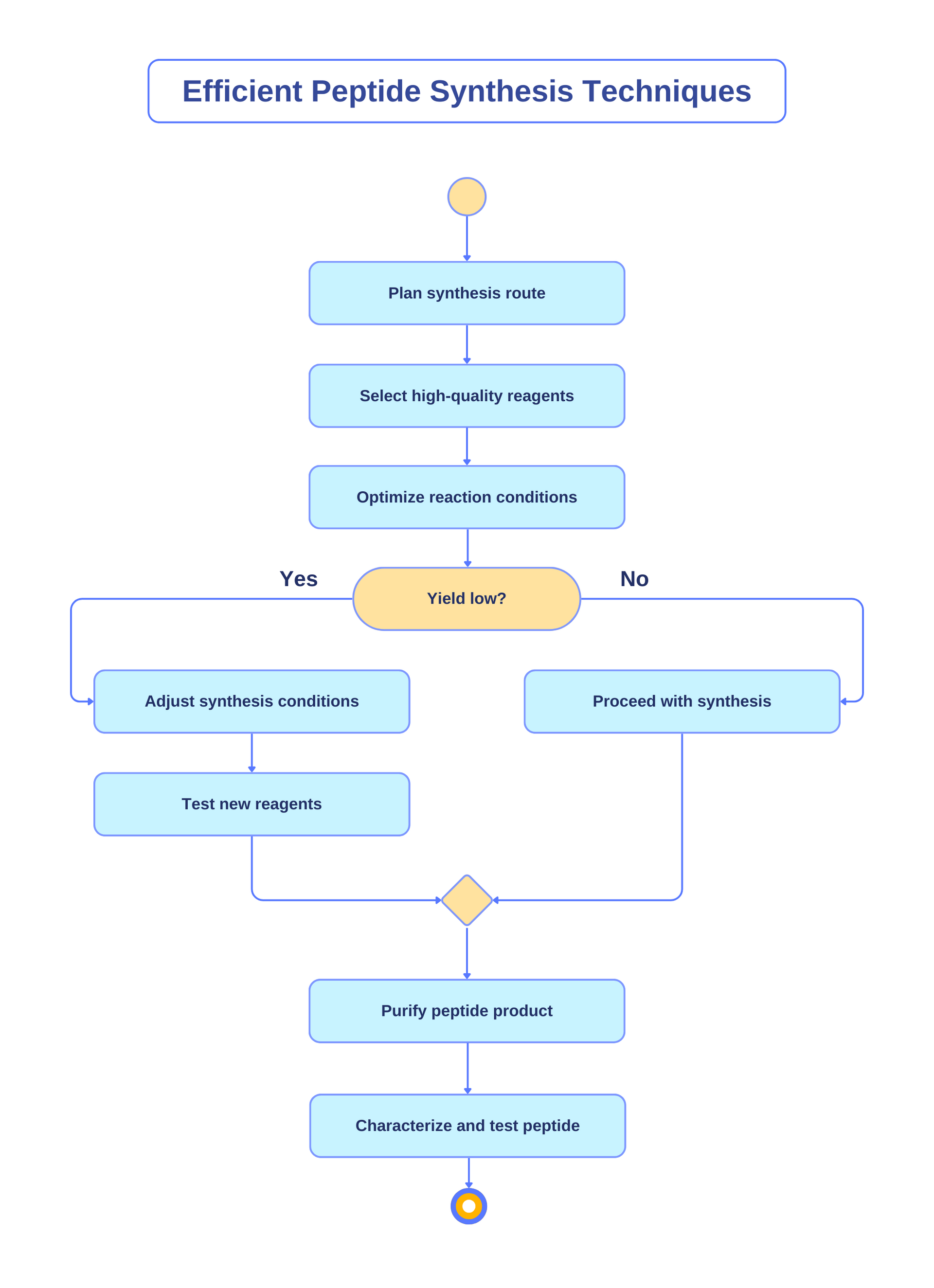

Chemical synthesis offers flexibility in creating complex peptide sequences that are often challenging for biological methods. It allows for customization and precise control over the peptide’s composition and sequence. However, challenges such as high material costs, scale-up difficulties, and solvent waste must be addressed to optimize the process. Additionally, the synthesis of long peptides or those with intricate secondary structures can be problematic due to incomplete coupling reactions and aggregation issues.

Liquid-Phase Peptide Synthesis (LPPS):

Liquid-phase peptide synthesis (LPPS) is another important method that involves the synthesis of peptides in a solution rather than on a solid support. LPPS is particularly advantageous for synthesizing longer peptide chains and peptides that are difficult to produce using SPPS.

Advantages of Liquid-Phase Synthesis

LPPS allows for more efficient synthesis of long peptide chains and reduces problems associated with incomplete reactions often encountered in solid-phase synthesis. The method provides greater flexibility in monitoring reaction progress and optimizing conditions, leading to higher purity and yield. Additionally, LPPS can be scaled up more easily, making it suitable for commercial production.

Challenges of Liquid-Phase Synthesis

Despite its advantages, LPPS faces challenges such as the need for extensive purification steps to remove by-products and the requirement for large volumes of solvents, which can increase costs and environmental impact. Furthermore, handling and manipulating peptides in a liquid phase can be more complex and time-consuming compared to solid-phase methods.

Recombinant Peptide Synthesis:

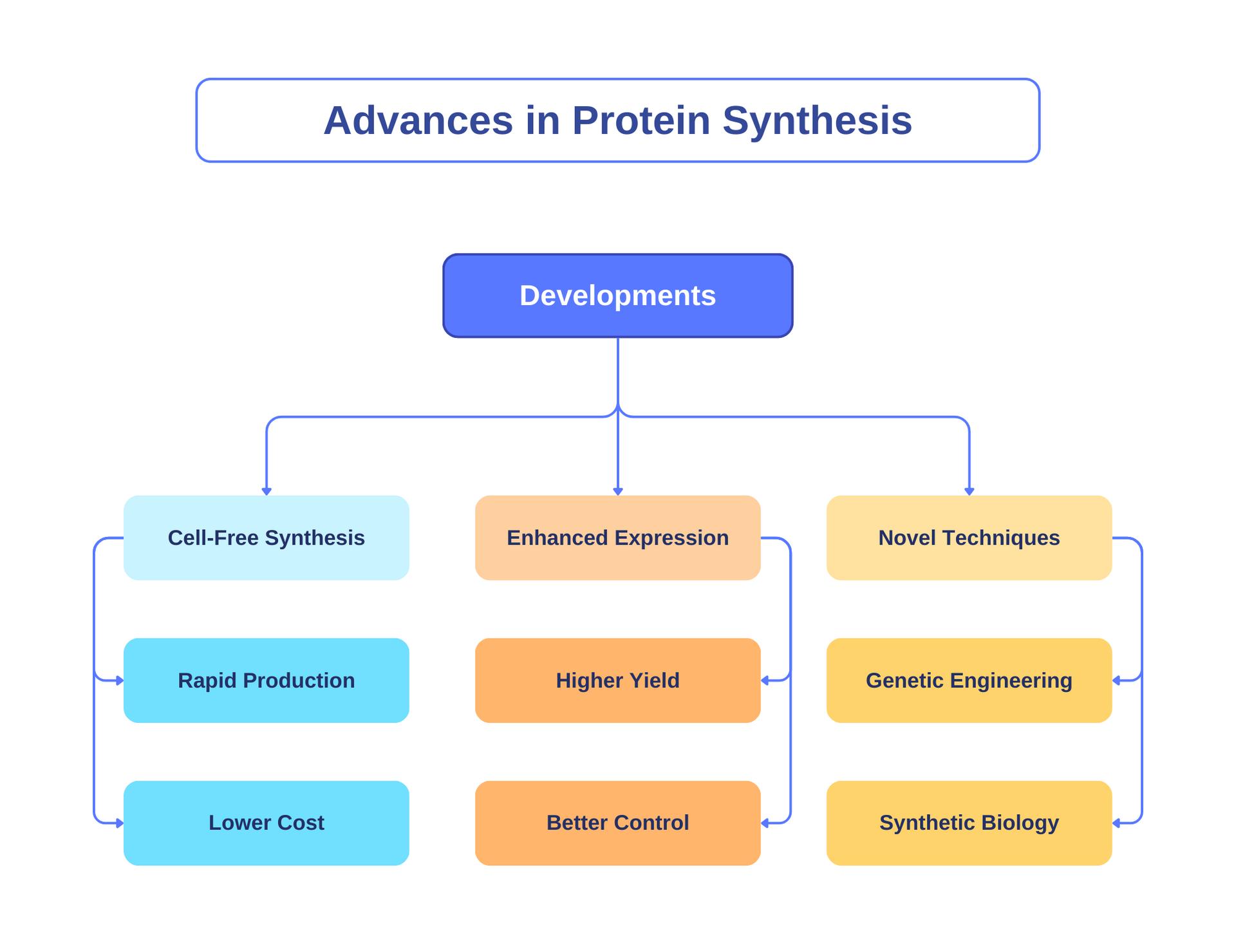

Recombinant peptide synthesis involves the production of peptides using genetically engineered organisms such as bacteria, yeast, or mammalian cells. This method is particularly useful for producing large quantities of peptides and allows for complex post-translational modifications that enhance peptide functionality.

Advantages of Recombinant-Phase Synthesis

Recombinant synthesis is cost-effective for large-scale production and supports the incorporation of complex tertiary structures and post-translational modifications. It also aligns with sustainable manufacturing principles by reducing chemical waste and energy consumption. Techniques such as codon optimization and the use of strong promoters can significantly enhance peptide yields in recombinant systems.

Challenges of Recombinant-Phase Synthesis

Despite its advantages, recombinant synthesis faces challenges such as complex purification needs, potential immunogenicity, lengthy development cycles, and limited ability to accommodate certain chemical modifications. The production of peptides with disulfide bonds or other specific structural requirements may necessitate additional folding and refolding steps, increasing the complexity and cost of the process.

Growing Demand for Peptide Synthesis Services:

The burgeoning field of life science research has led to an increased demand for peptide synthesis services. Peptides are indispensable in biomedical research, drug discovery, and therapeutic development. As our understanding of molecular biology deepens, the necessity for precise and reliable peptide synthesis continues to surge.

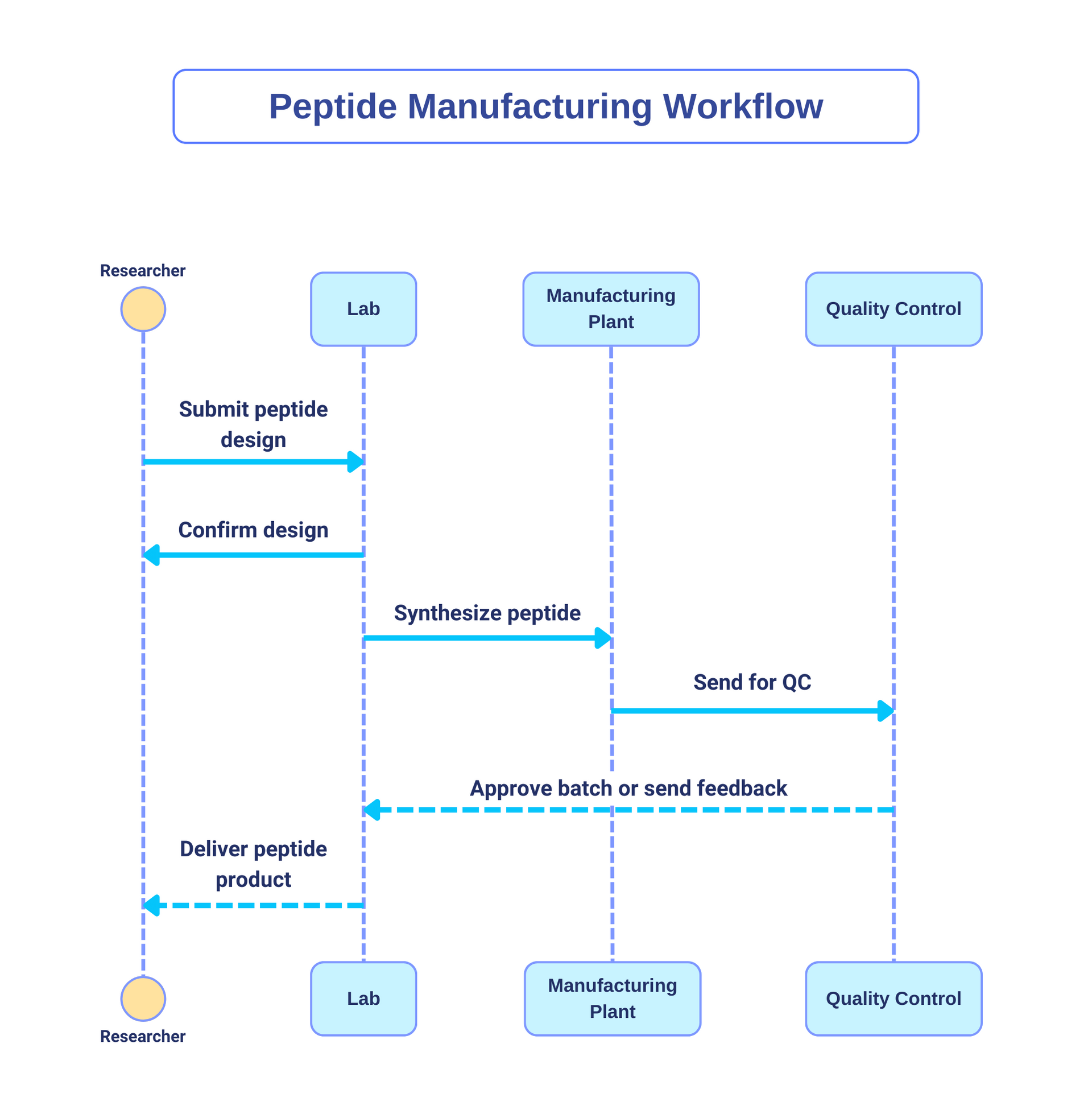

Investment in Advanced Technologies

To support the growing demand, it is crucial to invest in state-of-the-art synthesis technologies and methodologies. Advanced techniques such as SPPS and liquid-phase peptide synthesis (LPPS), coupled with rigorous quality control measures, are essential to meet the escalating demands of the scientific community. Innovations in automated synthesis platforms and high-throughput screening methods have significantly enhanced the efficiency and scalability of peptide production.

Hybrid Manufacturing Solutions:

The future of peptide synthesis lies in the development of novel hybrid manufacturing solutions that combine the strengths of both chemical and recombinant methods. These solutions are critical for producing high-quality peptides with the necessary modifications and at the required scales.

Advantages of Hybrid Approaches

Hybrid approaches offer the flexibility and precision of chemical synthesis while leveraging the efficiency and sustainability of recombinant methods. They enable the production of peptides with complex structures and modifications that are challenging to achieve with a single method. For instance, hybrid methods may involve the initial synthesis of a peptide backbone through SPPS or LPPS, followed by the incorporation of complex modifications or large-scale production using recombinant systems.

Challenges and Future Directions

Developing effective hybrid manufacturing solutions requires addressing challenges such as process optimization, scale-up issues, and regulatory compliance. Innovations in synthesis technologies, such as soluble-anchor based Molecular Hiving™ and MCSGP (multi-column solvent gradient purification) for continuous purification, are expected to drive advancements in this area. Additionally, the integration of advanced analytical techniques like mass spectrometry and NMR spectroscopy is essential for ensuring the quality and consistency of the synthesized peptides.

Conclusion:

The demand for peptide synthesis services is poised to grow significantly in the coming years, driven by advancements in life sciences and biotechnology. To meet this demand, the development of novel hybrid manufacturing solutions is essential. By combining the strengths of chemical and recombinant methods, we can create peptides with the desired quality, efficiency, and scale, ultimately benefiting healthcare and scientific research.

References:

- Carpino, L. A., & Han, G. Y. (1970). The 9-fluorenylmethoxycarbonyl amino-protecting group. Journal of the American Chemical Society, 92(22), 5748-5749.

- Barany, G., & Merrifield, R. B. (1980). Solid-phase peptide synthesis. Journal of the American Chemical Society, 101(10), 2686-2700.

- Gill, V. S., et al. (2017). Hybrid approaches to peptide synthesis. Biotechnology Advances, 35(8), 1213-1222.

- Fields, G. B., & Noble, R. L. (1990). Solid phase peptide synthesis utilizing 9-fluorenylmethoxycarbonyl amino acids. International Journal of Peptide and Protein Research, 35(3), 161-214.